Maintenance & Integrity Management

Hofincons endeavors to be one-stop service provider and can be an integral part of client’s implementation team for all Asset Maintenance & Integrity Management requirements, such as:

Criticality Analysis

The Functional Criticality analysis is top down identifying the various functions and sub-functions of the facilities. The level of a function is recognised by decomposing to a lower level. The aim of the Equipment Criticality Assessment is to develop equipment risk profile or identify the equipment that is most likely to cause the most loss to profitability, safety and the environment. It uses the risk formula to identify the business financial impact if an equipment was to fail. The criticality ranking is used along with safety, environmental and production performance standards to focus the maintenance strategy development.

Failure Mode Effect Analysis (FMEA) and Reliability Centered Maintenance (RCM)

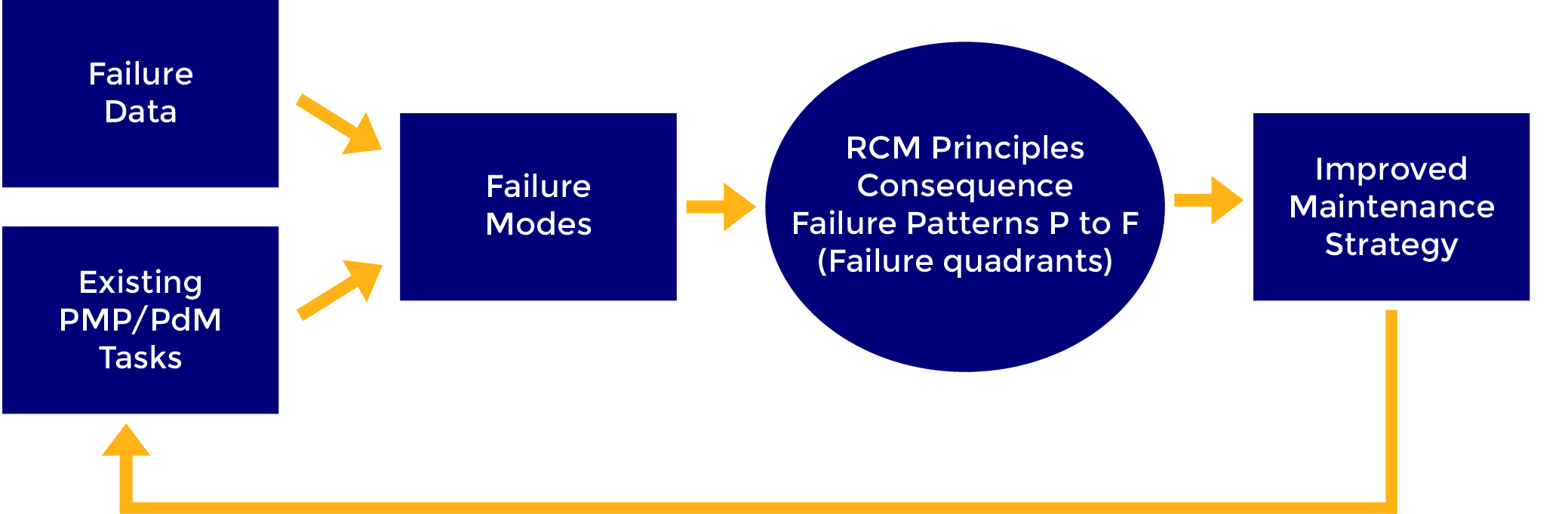

In order to improve the availability and reliability of assets and thereby improve maintenance effectiveness to achieve maximum return on Investment, an RCM analysis will be carried out by a team of skilled and qualified reliability and maintenance engineers from Hofincons by conducting interactive RCM workshop(s) with client team.

Maintenance Strategy Development by PMO

Maintenance optimization is a process that attempts to balance the maintenance requirements (legislative, economic, technical, etc.) and the resources used to carry out the maintenance program (people, spares, consumables, equipment, facilities, etc.).

The goal of the maintenance optimization process is to select the appropriate maintenance technique for each piece of equipment within a system and identifying the periodicity that the maintenance technique should be conducted to achieve regulatory requirements, maintenance targets concerning safety, equipment reliability, and system availability / costs.

Maintenance Strategy Development by RBI

Risk Based Inspection (RBI) is part of Risk & Reliability Management (RRM) and in-line with Asset Integrity & Reliability Management System (AIRMS). The study is carried out based on API 581 The dedicated RBI study will guide where, when and what type of inspection & monitoring is required for particular asset. The objective is to ensure focus of inspection to areas with high risk, while inspection in areas with low risk will be reduced from the normal inspection program.

Oman | Saudi Arabia | Sharjah | Malaysia | Abu Dhabi | Dubai | India | UK | USA

2019 Copyright | HOFINCONS IRCA GLOBAL All rights reserved.