Asset Data Management

Asset Data Management Services include:

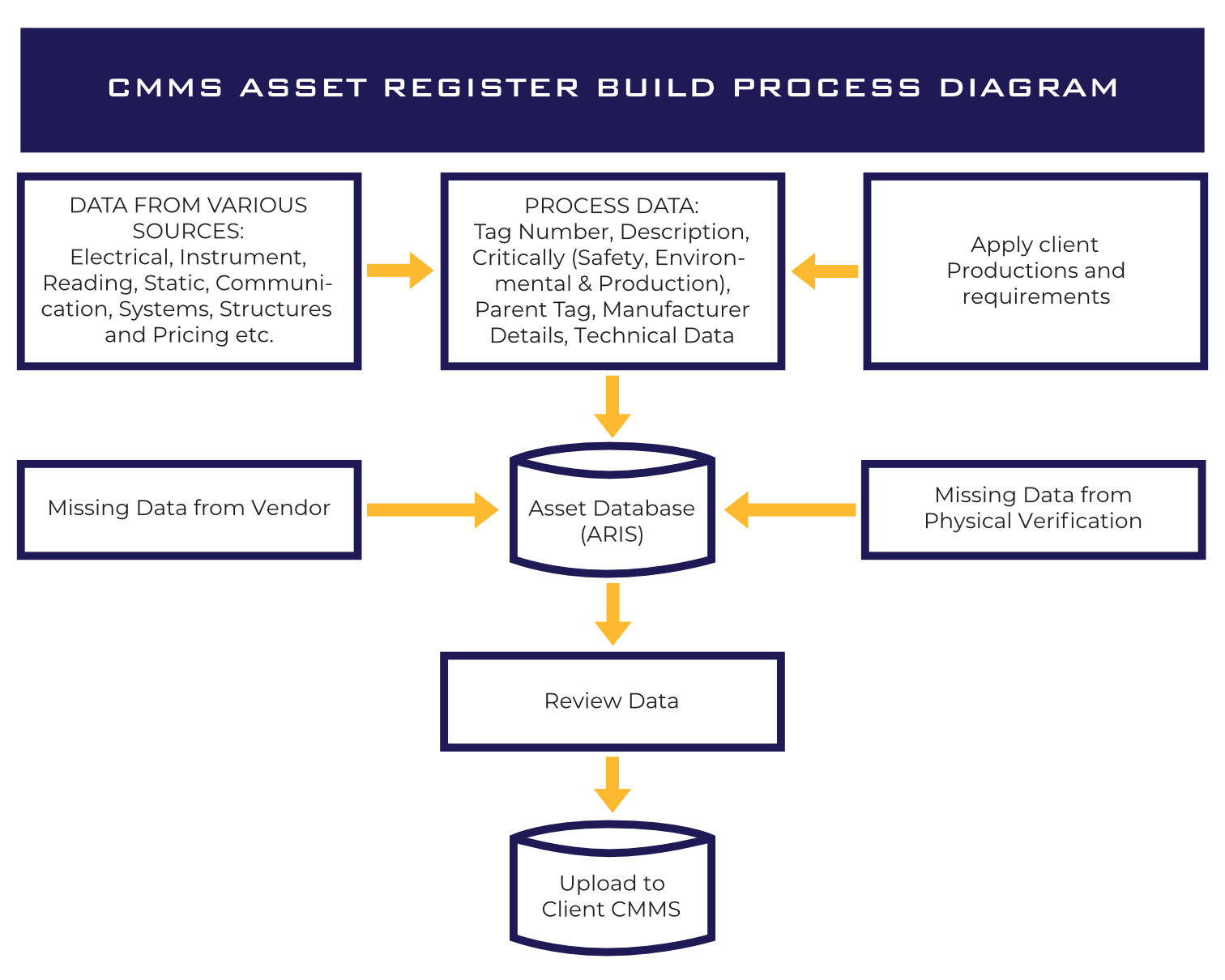

Asset Register Build

Asset Register and Maintenance data is the mandatory requirement to take-up maintenance activities for all the assets of an industry for its smooth operations.

Hofincons has a comprehensive approach to build maintenance data by capturing assets and their maintenance data from different sources, i.e. by reading P&IDs, Equipment data sheets, Equipment specifications, its location details & hierarchy as per the process flow, building BOMs by linking spares & sub-assemblies for any new PLANT / PACKAGE / EQUIPMENT additions, along with its planning data for smooth operations and maintenance requirements.

As-built Asset Verification

Hofincons has specialists with experience of developing As-builts through field physical verification. The data will be verified at field and will be provided to reflect the As-built status in the CMMS system and As-built drawing updates.

Asset Gap Study & Reporting

Asset Gap Analysis is the most effective method to implement asset performance improvement program where the plant operations management recognizes the need for an improvement in operations and maintenance when the priorities and opportunities are unclear.

Most industries will benefit by asset gap analysis, but the benefits will be highest where the cost of maintenance and the cost of failure is a high proportion of total operating cost.

In order to improve the availability and reliability of assets and thereby improve maintenance effectiveness to achieve maximum return on Investment, an asset gap analysis program can be carried out by conducting an interactive workshop(s) by a team of skilled and qualified reliability and maintenance engineers from Hofincons and client’s operations and maintenance team.

Asset Gap Analysis will give a clear road-map for setting action priorities to close the gap between existing practice and the best industry practice for effective asset management. It helps to identify opportunities for continuous improvement through PMO and RCM and or other practices for cost and reliability improvements.

Asset Data Cleansing & Restructuring

The Asset maintenance data which is existing in various sources will be verified and cleansed and enriched data will be uploaded to the client CMMS system. Appropriate maintenance data will be prepared reflecting the restructured asset hierarchy with functional location/tag and maintenance tasks with planning data & work orders.

Oman | Saudi Arabia | Sharjah | Malaysia | Abu Dhabi | Dubai | India | UK | USA

2019 Copyright | HOFINCONS IRCA GLOBAL All rights reserved.